Samko Timber Limited and its subsidiaries (”Samko” or “Samko Timber” or the “Group”) is Indonesia’s leading, vertically integrated wood resource processor. Supported by 35,659 ha of industrial forest plantation in Sumatra, Samko operates six timber processing plants, ten satellite veneer plants and a chemical glue facility spread across Java, Sumatra and Sulawesi with an annual production capacity of approximately 800,000 m3 .

Samko Timber Limited dan anak perusahaannya ("Samko" atau "Samko Timber" atau "Grup") merupakan perusahaan prosesor bahan baku kayu terintegrasi di Indonesia. Didukung dengan 35,659 hektar perkebunan hutan industri di Sumatra, Samko memiliki enam pabrik pemrosesan timber, sepuluh pabrik satelit veneer dan fasilitas produksi lem kimia yang tersebar di pulau Jawa, Sumatra dan Sulawesi dengan sekitar 800,000 m3 kapasitas produksi per tahun.

With unrelenting focus on excellence at every stage of its supply chain, Samko has garnered international environmental accreditations as a testament of its long term commitment to quality and sustainability. The Research and Development department is tasked with ongoing process improvement, wood maximisation and product innovation, setting the stage for value creation and growth.

With close to 40 years of experience and industry knowledge condensed into its primary and secondary processed timber products, Samko’s products are found in residential, commercial and industrial applications in the form of plywood, wood-decking, wood-doors, wood-flooring, piano and truck parts. Samko’s products enjoy a dominant market share in Indonesia, and are distributed in more than 28 countries across the world, including the Asia Pacific region, Europe, the Middle East, and the United States of America.

Selalu berfokus pada keunggulan disetiap area di supply chain, Samko memiliki sejumlah akreditasi lingkungan bertaraf internasional sebagai bukti akan komitmen perusahaan dalam memastikan terjaganya kualitas dan kebersinambungan. Departemen Riset & Pengembangan ditugaskan untuk selalu menghadirkan kemajuan atas proses produksi, maksimalisasi timber dan inovasi produk untuk menyusun langkah menuju kreasi nilai dan pertumbuhan Perusahaan.

40 tahun pengalaman dan pengetahuan industri yang dituangkan kedalam proses primer dan sekunder dalam produksi timber membuat produk-produk Samko mudah ditemui di area residensial, komersial dan industrial dalam wujud plywood, wood-decking, wood-doors, wood-flooring, piano dan truck parts. Produk-produk Samko memiliki nilai saham yang dominan di Indonesia, dan telah didistribusikan ke lebih dari 28 negara di dunia, termasuk Asia Pasifik, Eropa, Timur Tengah dan Amerika Serikat.

History

Since the commencement of our operations in 1978, Samko Timber Limited has come a long way. Under the leadership of our founder and chairman Mr Koh Boon Hong, we started out as a downstream processed timber products manufacturer without natural forest concessions and industrial forest plantations. Our first operation was started in Sulawesi, producing 12,000 m3 of plywood annually. Since then, we have grown both through organic expansions as well as through acquisitions to become one of the major wood processing companies in Indonesia.

Over the past 30 over years, we have focused extensively on developing our research and development, management, processing and logistics and distribution capabilities so as to achieve a competitive edge over our competitors. We have developed a strong business and operating model, enabling us to continuously expand our processing capacity to become one of the biggest players in Indonesia.

Today, we have established a strong market position, as a leading processed timber products company in Indonesia and one of the top five tropical hardwood plywood producers globally.

In February 2008, we were successfully listed on the Mainboard of the SGX-ST, marking the beginning of another new chapter in our corporate history.

Samko Timber Limited telah berkembang pesat sejak pertama kali beroperasi di tahun 1978. Didirikan dan dipimpin oleh Mr. Koh Boon Hong, Samko Timber Limited berawal dari manufaktur produk-produk kayu proses tanpa konsesi hutan alami dan perkebunan hutan industri. Pabrik pertama kami didirikan di Sulawesi, menghasilkan 12,000 m3 plywood per tahunnya. Sejak saat itu kami telah tumbuh dan berkembang baik melalui ekspansi organik maupun melalui akusisi untuk menjadi salah satu perusahaan kayu proses terbesar di Indonesia.

Selama lebih dari 30 tahun fokus kami diutamakan untuk mengembangkan departemen riset & pengembangan, manajemen, kemampuan proses produksi, logistik dan distribusi untuk dapat mengungguli kompetitor kami. Kami telah membangun usaha dan model operasi yang kuat, yang memberikan kami kemampuan untuk terus mengekspansi kapasitas produksi kami dan menjadi salah satu pemain terbesar di Indonesia.

Hari ini, kami memiliki posisi kuat di pasar sebagai pemimpin perusahaan proses timber di Indonesia dan satu dari lima produsen tropical hardwood plywood terbesar di dunia.

Pada Februari 2008 kami telah sukses terdaftar di Mainboard of the SGX-ST, menandai awal mula babak baru di sejarah korporat kami.

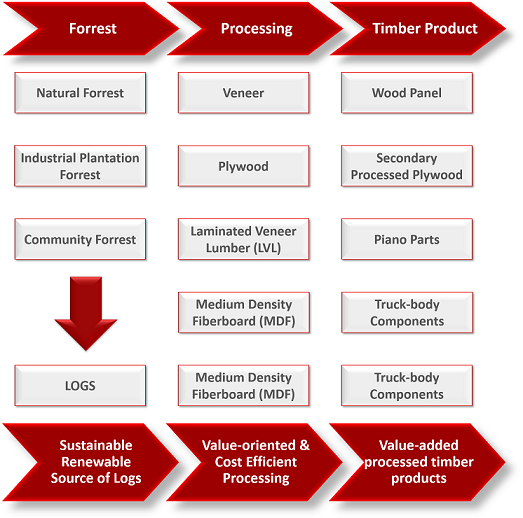

Our Business Model

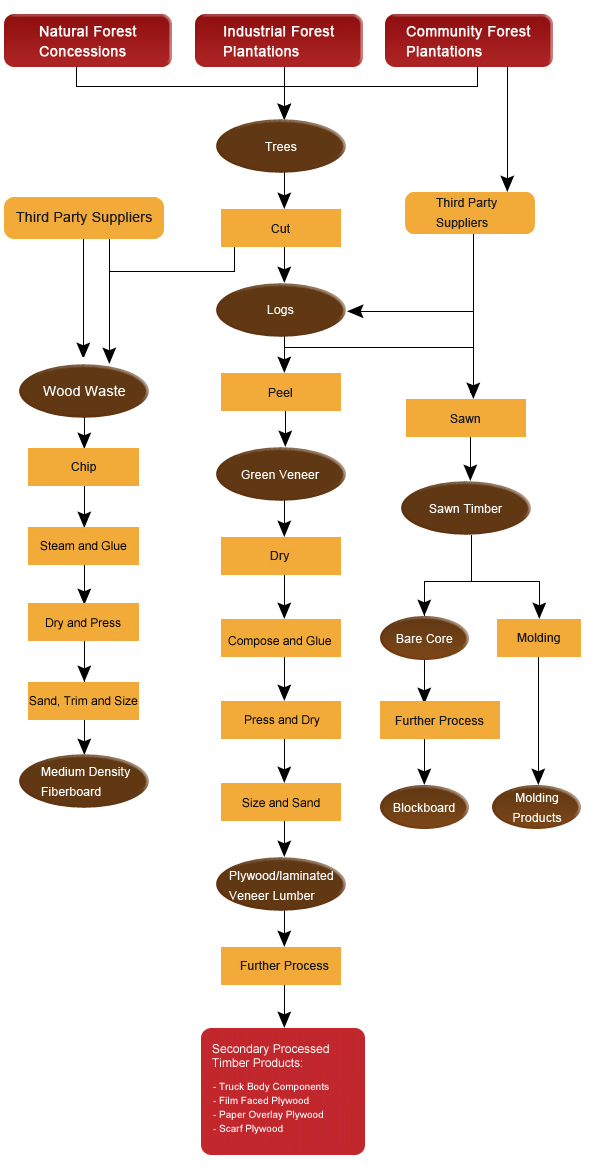

Samko Timber Limited obtains the logs for the production of our processed timber products from our industrial forest plantations, natural forest logs purchased from third party log suppliers, as well as plantation logs purchased mainly from community forests and plantations in Java and Sumatra. We believe that we are one of the first timber processing companies in Indonesia to use plantation logs for veneer production.

We have put a lot effort into capturing the maximum value of wood used at our production sites, especially in our strategy to increase usage of smaller diameter plantation logs. The percentage of wood that is successfully extracted as sheets is referred to as recovery rate. High recovery rates means that a greater proportion of the wood value is captured through the conversion into higher value products.

Sumber bahan baku kayu yang digunakan dalam proses produksi di Samko Timber Limited berasal dari perkebunan hutan industri yang kami miliki, kayu hutan alami hasil pembelian dari pihak ketiga (log suppliers) dan juga pembelian dari hutan komunitas dan perkebunan-perkebunan di pulau Jawa dan Sumatra. Kami percaya bahwa kami adalah salah satu perusahaan kayu proses di Indonesia yang menggunakan kayu dari perkebunan untuk produksi veneer.

Kami berusaha memaksimalkan nilai dari kayu yang kami gunakan di proses produksi, terutama dalam mengembangkan strategi untuk meningkatkan penggunaan kayu berdiameter kecil. Presentase kayu yang berhasil diekstrak menjadi lembaran disebut "Recovery Rate". Recovery rates yang tinggi menandakan tingginya proporsi atas nilai kayu yang didapatkan setelah melalui proses konversi untuk menjadi produk-produk bernilai tinggi.

Overall Business Model

Timber Processing

Our processed timber products are produced in varying grades, sizes, thicknesses and appearances, depending on the particular needs of our customers.

Produk-produk kayu proses kami diproduksi dalam berbagai variasi grade, ukuran, ketebalan dan tampak luar, sesuai dengan kebutuhan spesifik dari pelanggan kami.

They include primary processed timber products such as:

Produk kami termasuk primary processed timber, yaitu:

- • Primary plywood

- • Laminated veneer lumber

- • Piano parts

and a range of secondary processed timber products such as:

dan serangkaian produk secondary processed timber, yaitu:

- • Processed plywood

- • Truck body components

- • Wooden house components

Plywood

In plywood production, a log is peeled into sheets of veneer which are then cut to the desired dimensions, dried, patched, glued together and then pressed under high temperature press to form the plywood panel. Depending on the type of log (quality, colour etc.) peeled, the veneer sheets will become either face or back veneers, which are the furthest outer layers of the plywood panel, or core veneers which will form the inside layers.

Pada produksi plywood, batang kayu dikupas menjadi lembaran veneer yang kemudian dipotong dengan dimensi yang diinginkan, dikeringkan, disusun, direkatkan dan di press dengan menggunakan press suhu tinggi yang akan menghasilkan panel plywood. Tergantung tipe batang kayu (kualitas, warna, dsb) yang dikupas, lembaran veneer tersebut akan menjadi face atau back veneer, yang merupakan lapisan terluar panel plywood, atau menjadi core veneer yang membentuk lapisan kayu dibagian dalam panel.

Laminated Veneer Lumber (LVL)

LVL is produced through a similar process as plywood, but usually to thicker panels.

All of these panel products are primarily used in construction, furniture and interior decoration industries. In addition to these, we produce plywood products that are specialised, further processed products. These include film-faced plywood, piano parts as well as truck body components. These products fetch higher margins and are for specialised end-uses.

LVL diproduksi melalui proses yang mirip dengan proses pembuatan plywood namun dengan ketebalan yang lebih tinggi.Seluruh produk-produk panel utamanya digunakan di industri konstruksi, furnitur dan dekor interior. Selain daripada itu, kami memproduksi produk plywood yang terspesialisasi dan melalui proses produksi yang lebih jauh. Hal ini termasuk film-faced plywood, piano parts dan juga komponen badan truk. Produk-produk ini memberikan margin yang lebih tinggi dan untuk penggunaan akhir yang berspesialisasi.

Our Seven Eco-Friendly Products

- Eco-floor Based Plywood for all your flooring solutions (solusi flooring yang anda butuhkan)

- Laminated Veneer Lumber (LVL) and Laminated Veneer Board (LVB) for door and window frames, house beams and frames; and floor joists (untuk bingkai pintu dan jendela, kerangka rumah dan lantai balok)

- "Heveatech" branded LVL: attractive, durable and insect resistant wood for decking, fencing and frames (menarik, kuat dan kayu tahan rayap untuk kebutuhan decking, pagar dan kerangka/bingkai)

- General Plywood for a wide range of selective building solutions, including cladding, partitions, door covers, and concrete forms (solusi pembangunan yang beragam, termasuk cladding, partisi, lapisan pintu dan konkrit)

- Doors customized for houses, restaurants, galleries, offices and other commercial premises (kustom untuk rumah, restoran, galeri, kantor dan ruang komersil lainnya)

- Precision Piano Body Parts

- Truck Parts: environmentally treated rubber-wood replaces traditional solid-wood bodies for flat decks and trunks, side panels and high-finish interiors (kayu karet olahan sebagai alternatif dari badan solid-wood tradisional untuk dek dan peyi, panel samping dan interior high-finish)

They include primary processed timber products such as:

Produk kami termasuk primary processed timber, yaitu: